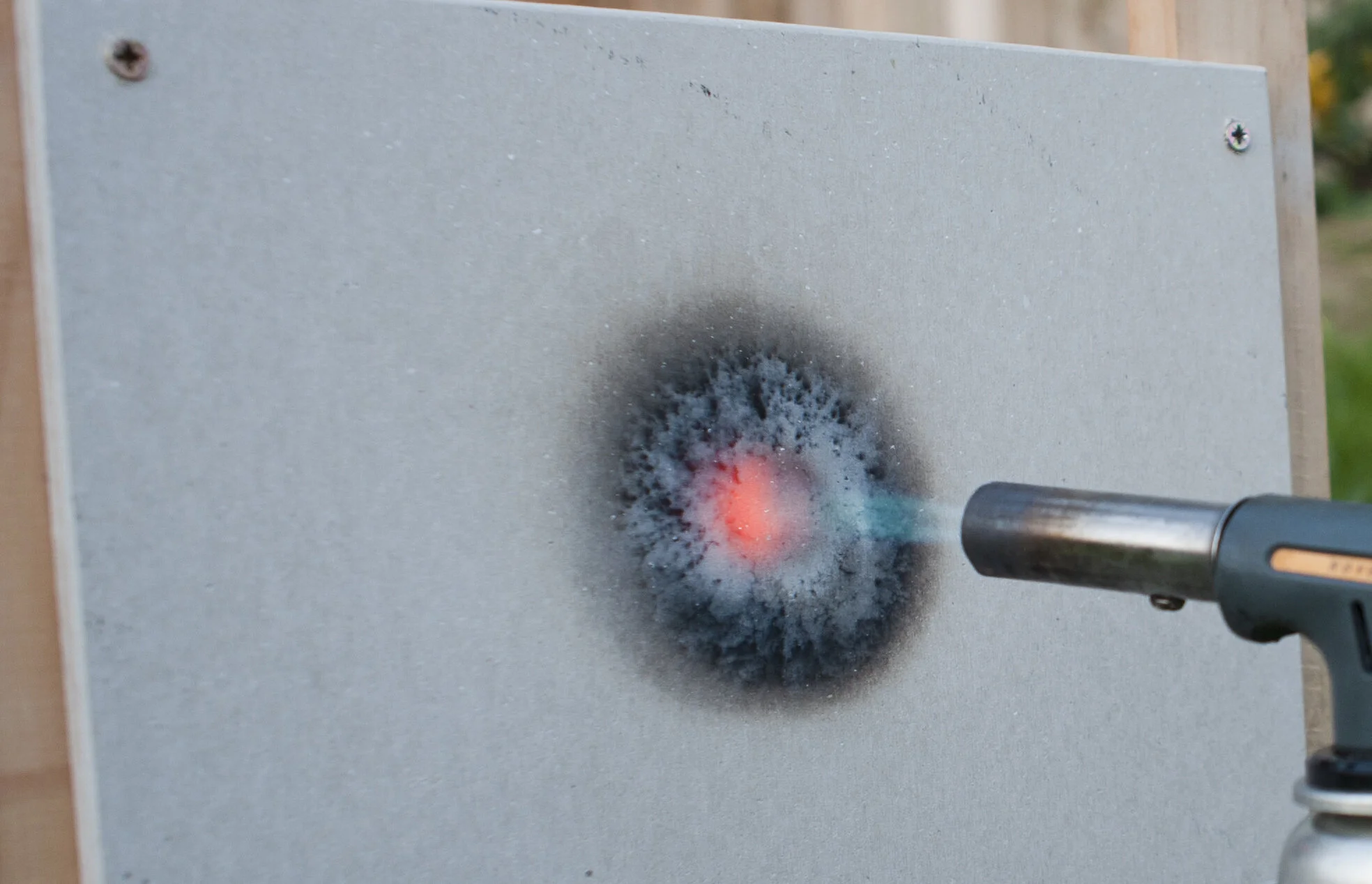

KAPO Board has an excellent fire performance; it is not a combustible material. If a fire occurs, the plate will not burn and will not produce toxic smoke. Achieved Group 1S tested by BRANZ.

Has excellent acoustic support: wall assembly on a12mm achieved 49 STC. Approved by Marshall Days Acoustic

Has superior moisture & mould resistance properties. Even when it absorbs moisture, it will regain its full strength upon drying without compromising its long-term performance.

has 40% less dust when cutting comparison with fiber cement board.

One price covers many area

F2.3.1 Non-hazardous material used

No special tool or diamond blade require to cut KAPO Board.

All KAPO Board comes with 20-year warranty. It must adhere to a manufacturer-recommended maintenance programme.

Why kapo board has such a good performance?

KAPO Board is made of calcium silicate, a medium-density of 1.1 - 1.5kgm3. It is an asbestos-free thermal insulation product that can withstand continuous high operating temperatures. It is a lightweight, low thermal conductive, high strength, easy to install, reliable and durable product. Industrial grade piping and equipment insulation are often fabricated from calcium silicate. It is a free-flowing white powder obtained by reacting calcium oxide and silica. It has a low bulk density and high physical water absorption.

Calcium Silicate Boards are manufactured from a mixture of Portland cement, fine silica, unique cellulose fibres and selected fillers to impart durability, toughness and moisture resistance. The calcium Silicate Sheet is then cured by an autoclaving process whereby the ingredients are reacted together under heated steam and high pressure.

The synthetic cement silicate binder provides exceptional dimensional stability and unrivalled resistance to movement due to the effects of moisture or heat. Calcium Silicate Board does not contain any ingredients or free alkali that could be dissolved by moisture or condensation. If exposed to moisture, the board will completely recover on drying out, with no permanent loss of strength.

Calcium Silicate boards will not degrade with time, and within standard applications, the life of the product is limited only by the durability of the supporting structure and materials used in fastening. Calcium Silicate Board will not rot or support fungal growth and is unaffected by sunlight or steam. Calcium Silicate boards are designed to use in applications, where impact resistance, fireproofing, waterproofing, sound adsorption and heat isolation are required.

cQualities of Calcium Silicate Insulation

High density 1.2 g / cm3 and 1.4 g / cm3,

Low thermal conductivity,

Good thermal resistance,

Fire-proof Group 1-S, BRANZ,

High strength,

Light weight,

Durable,

Easy to install,

Will not rot or support fungal growth,

Unaffected by steam,

Sound insulation,

Highly resistant to termites and attacks from other vermin.

Calcium Silicate Board applications

Soffit

For internal walls, partitions and ceilings: as a wet and heat lining

As the underlay board for floor and wall tiling,

For decorative applications,

Fire protective solution.

Frequent Ask Question?

Is KAPO Board a New Zealand appraised product?

Yes, KAPO Board is tested and appraised by BEAL laboratory.

What is KAPO Board?

KAPO Board is a Calcium silicate wall lining. The primary raw ingredients are:

Crystalloid of Calcium Silicate, quartz powder, calcium carbonate and cellulose.

It is an advanced production technology of moulding, pressure, high-temperature steaming and other innovative technical processing to made calcium silicate board.

Is KAPO Board fire resistance and is it test in New Zealand?

Yes, KAPO Board has achieved Group 1S tested by BRANZ.

Also, when the KAPO Board flamed up, KAPO Board will not produce any toxic, corrosive, and suffocating gas in comparison to fibre cement board.

Does it require a new walling system for installation?

No, KAPO board is suitable to use on the traditional system of Fibre Cement or Gypsum board.

We are not inventing the whole new wheel, just introducing a better tyre with better performance.

Is KAPO Board a hazardous product?

No, KAPO Board is 100% hazardous-free and 100% asbestos-free wall lining product.

Why choose to use KAPO Board than Fibre-cement Board?

As a new green building material, it functions as traditional gypsum board; calcium silicate board has superior fire performance and resistance to the tide, it often used for insulation layer application of external insulation board.

Benefits using KAPO Board

As a new green building material, in addition to the function of the traditional gypsum board, calcium silicate board has superior fire performance and resistance to tide, it often used for insulation layer application of external insulation board. The calcium silicate board has various performance advantages.

1. Long service life

Calcium silicate board performance is stable, due to siliceous, calcium material in the conditions of high temperature and pressure, the reaction is substantial to the production of the tropic crystal, the crystal as the main component of calcium silicate board, it is not easy to corrosion, it will not be moisture or pests and other damage, it can guarantee a long service life;

2. Fire Resistant / Fire Retartant

Traditional wood products will spread in a short time and produce a large number of toxic smoke and harmful substances in the event of a fire. It compared with wood products, calcium silicate board fireproof performance to the highest level of NZBC Verification Method C/VM2, in Appendix A, Group 1S to ensure that users’ fire safety;

3. Water and moisture resistant

The low water absorption and moisture content of calcium silicate board are the wood products cannot be replaced, and its excellent waterproof performance, even in the bathroom and other high humidity applications’ environment, it can avoid other similar products prone to expansion or deformation phenomena. Its superior waterproof, moisture-proof performance is the same type of products cannot be replaced;

4. Lightweight

Plate density between 1.2 g / cm3 and 1.4 g / cm3, it about 30 to 40 kg of per square calcium silicate board do not constitute an additional load problem to new and old building structures and walls.